RAGAGEP, RAGAGEP, and more RAGAGEP –

RAGAGEP – Recognized and Generally Accepted Good Engineering Practices. We have found in our recent freedom of information requests a large percentage of PSM/RMP citations falling into flow diagrams, RAGAGEP, procedures, MOC’s, and Mechanical Integrity. Recall, even though RAGAGEP is called out in PSM/RMP, it not only applicable to PSM/RMP facilities. You must have defense that your process and equipment complies with recognized and generally accepted good engineering practices. The document alone will not suffice, but a facility that implements the spirit of the publication. If you need help with RAGAGEP, training, or a safety evaluation we are here to give you a hand.

At a minimum we suggest that you companies declare your RAGAGEP (through a letter-to-file) and evaluate through an audit or gap analysis if they meet what they said they would follow. Some companies will make blanket statements that we follow “IIARâ€. That is so vague and similar language is we follow all of this _______ political party. You can’t follow all of IIAR. Some of their material through time and various documents contradict themselves. When a company says they follow IIAR 2, that is getting a little more in detail, however what year of publication and addendum? About every 3 to 5 years these RAGAGEP’s get new publication and addendums in between. There is quite a difference of best practices between IIAR 2 – 1992 and IIAR 2 – 2021. The most current version of IIAR 2 has approximately 800 SHALLS and 50 SHOULDS that need to be addressed, evaluated, and implemented in your facility. If your facility has outdated RAGAGEP, please see this post.

IIAR Standard 9 states as of March 3, 2025, every facility (regardless of quantity of ammonia onsite) must have an initial minimum safety evaluation. This evaluation will re-occur every 5 years and can be incorporated into the function process of a PHA. Also, any modification to your existing system must be made in the spirit of the most current version of IIAR 2.

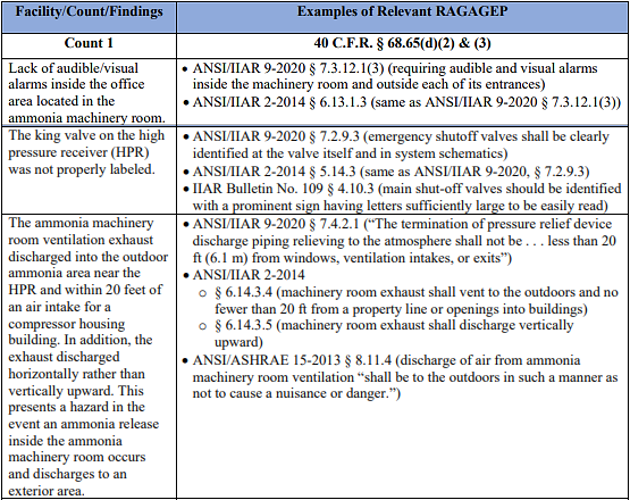

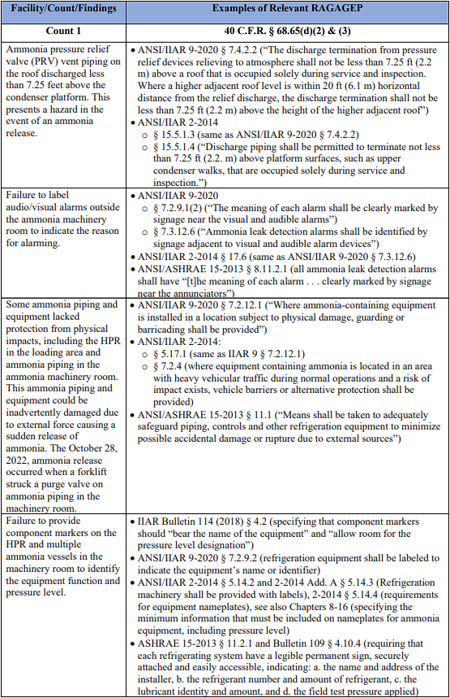

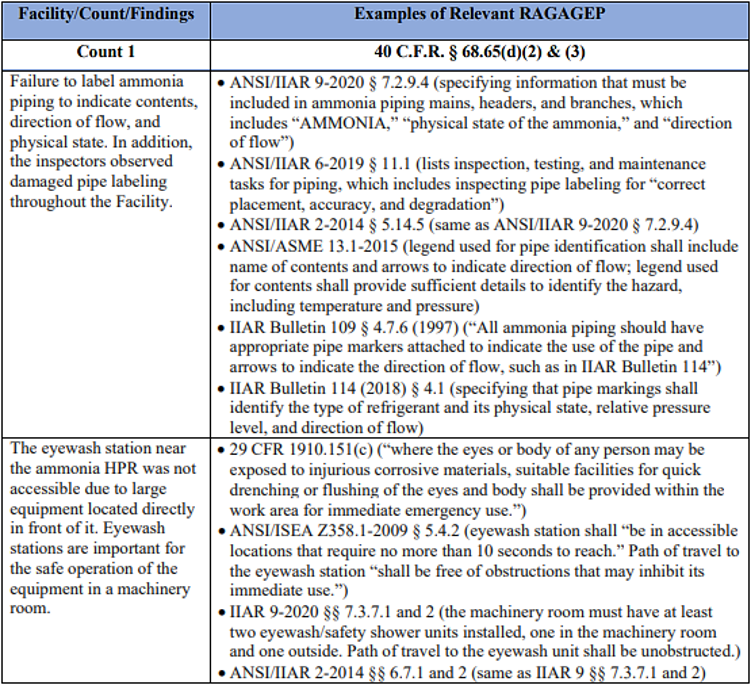

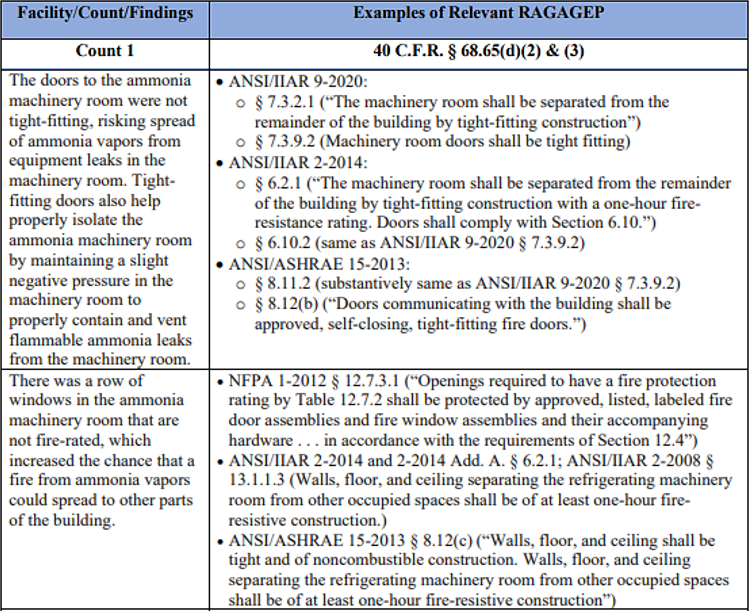

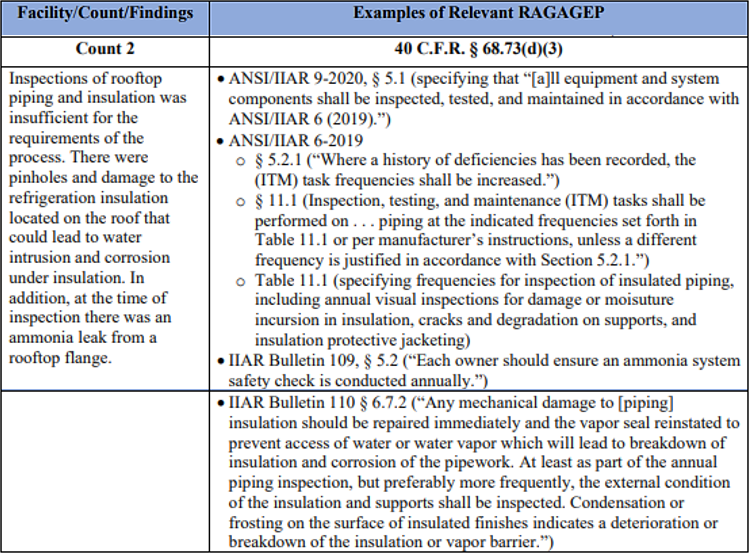

An EPA inspection revealed that an ammonia refrigeration facility failed to document that its ammonia refrigeration equipment complied with RAGAGEP. This included issues like missing ammonia alarms, inadequate labeling of critical equipment, and failure to adhere to engineering best practices in equipment installation. A national ice cream manufacturer, agreed to pay a penalty of $115,849 to settle claims by the U.S. Environmental Protection Agency that it violated federal laws regulating the handling and storage of ammonia at its facility in Suffield, Conn. As part of the settlement, the company has also agreed to complete system safety audits of its six facilities nationwide that have requirements under the risk management program (RMP) regulation.

“When a company falls short in meeting its safety obligations, it puts workers, local communities, and the environment at risk. With the company operating facilities across the country, we have a duty to call out a lack of accountability when we see it,” said EPA New England Regional Administrator David W. Cash. “Ensuring safety and management practices of hazardous substances is key. We are dedicated to our core mission of protecting all communities, specifically focusing on mitigating environmental pollution and minimizing risks. This case serves as a reminder to companies that accountability and compliance is important. Chemical accident planning, prevention, and mitigation requirements, are all steps we make certain of, in order to keep New England safe.”

In addition, the company failed to comply with the mechanical integrity requirements of the Clean Air Act’s chemical accident prevention regulations by allegedly failing to sufficiently conduct piping inspections. Instances of damaged pipe insulation with potential safety risks and a minor anhydrous ammonia leak from a valve were documented. These findings highlighted the need for improved safety measures and adherence to industry standards at this facility, and at the other five other facilities with risk management plan (RMP) requirements nationwide. The penalty also includes a separate EPA assessment regarding a recent ammonia release from this company, caused by a forklift impact. In addition, the company must take steps to protect pipes in the machinery room from future forklift impacts.

Below are becoming far too common.

Ammonia Refrigeration Training Solutions – ARTS